Products

H2O2 Biodecontamination

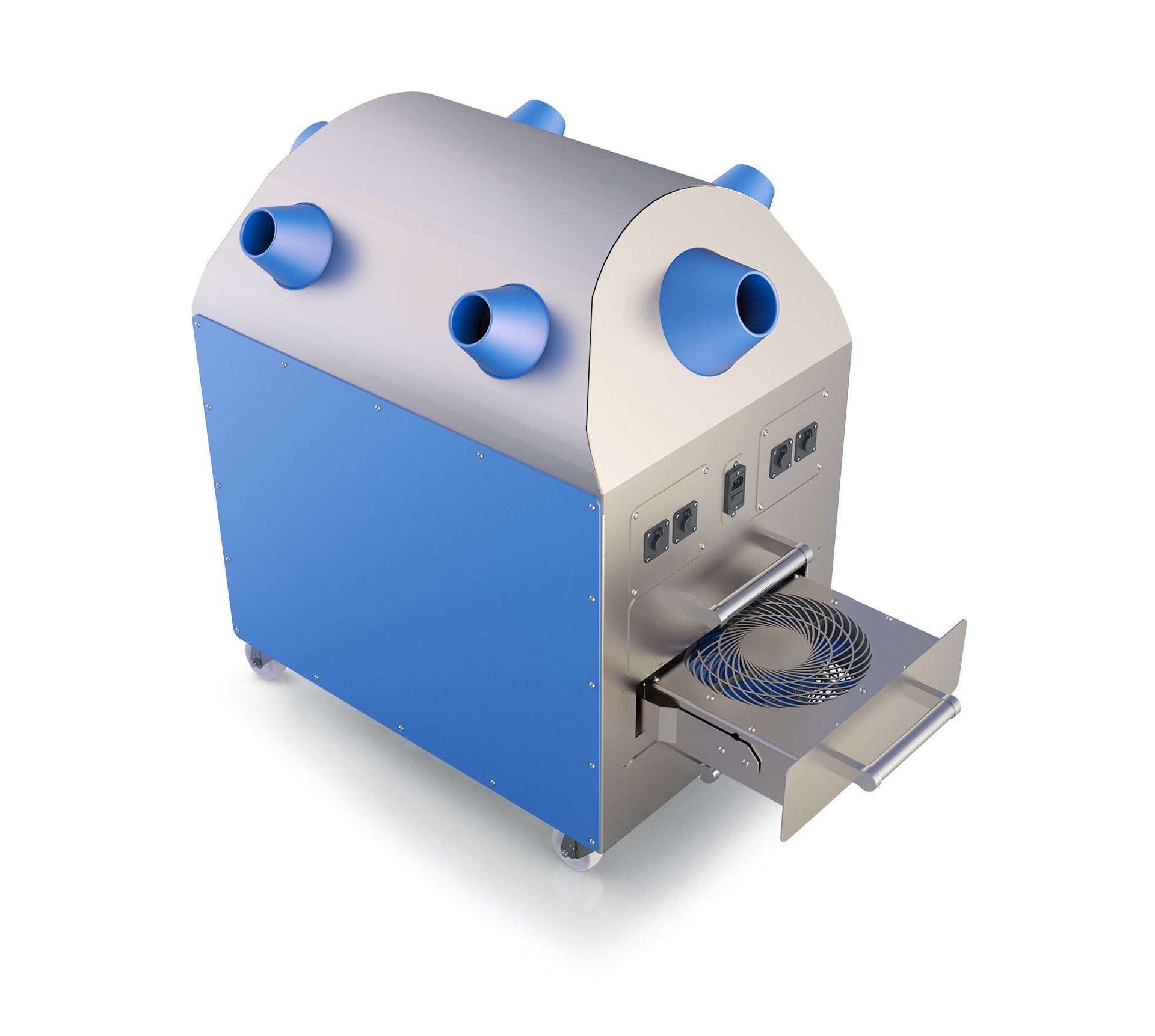

Bioreset.

Innovative hydrogen peroxide V-Phase biodecontamination solutions

Innovative hydrogen peroxide V-Phase biodecontamination solutions

Using vapour-phase hydrogen peroxide (H2O2 V-Phase) as a cold sterilising agent, Bioreset is the most technologically advanced, effective, rapid bio-decontamination system.

Removable microorganisms.

BACTERIA: Bacillus, Clostridium, Mycobacterium, Listeria, Lactobacillus, Enterococcus, Staphylococcus, Enterobacter, Escherichia, Klebsiella, Serratia, Salmonella, Yersinia, Legionella, Acietobacter, Pseudomonas, Acholeplasma.

VIRUS: Herpesviridae, Iridoviridae, Poxviridae, Adenoviridae, Orthomyxoviridae, Paramyxoviridae, Parvoviridae, Rhabdoviridae, Flaviviridae, Arenaviridae, Caliciviridae, Picornaviridae, Reoviridae.

FUNGI: Alternaria, Aspergillus, Blastomyces, Candida, Coccidioides, Histoplasma, Penicillium.

Bioreset solutions are mainly used to remove the airborne and surface microbiological contamination in controlled or classified environments for pharmaceutical, biomedical, biotechnological, animal care and in any other environment where microbiological contamination is a concern.

Vaporized hydrogen peroxide efficiency.

Mentioned by Food & Drug Administration (FDA), Environmental Protection Agency (EPA), United States Pharmacopeia (USP) and other regulatory agencies around the world as a surface sterilization agent.

Vapour-phase hydrogen peroxide advantages.

PROVED EFFICACY: tested to kill a wide range of microorganisms and viruses. H2O2 in vapor-phase allows a uniform distribution to reach also the most difficult areas of the environment. It is capable of a 6 Log reduction on all exposed surfaces.

EXCELLENT COMPATIBILITY: Hydrogen Peroxide has chemical-physical characteristics that are compatible with many materials – such as metals, plastics, elastomers, and all electronic devices.

UNBEATABLE SPEED: the low working temperature and the efficacy of the vapor-phase H2O2 allow a cycle time that is attractive to a wide range of applications, and offers a rapid recovery of the production activity.

SAFE TO USE: at the end of each biodecontamination cycle, H2O2 is removed in the most effective way according to the application. Decomposing into water and oxygen, it is not dangerous for the operator and it is safe for the environment.

NO RESIDUE: in vapor-phase, it leaves no residue on the surfaces and no post cycle cleaning is necessary.